Effortless Loading, Unmatched Efficiency

Introducing our Loading dock leveler, which is the standard equipment for logistics warehouses to move goods in and out. The dock leveler works together through the control system, electro-hydraulic power unit, adjusting plate, and tongue plate, which can effectively adjust the height difference between the bottom of the carriage of different transport vehicles and the platform, forming a transitional board between the vehicle and the platform, and improving the efficiency of loading and unloading.

The dynamic load rating is 6.3T, and the static load rating is 13.6 T. The bodyguards on both sides are automatically retractable to ensure safety. Dock leveler has a wide range of applications in the modern logistics industry, which can ensure the safety of goods, improve logistics efficiency, and reduce operating costs.

4 Advantages Of Megodoor Dock Leveler!

Advanced Lip Structure

Lip thickness can be customized to 40 cm or 50 cm. The platform table is made of a non-slip tread plate, which has a large bearing capacity and wear resistance. The lip is designed with a strong and stable structure and is integrally reinforced to ensure reliability and durability during loading and unloading.

Stronger Load Carrying Capacity

The load capacity of 6T/ 8T/ 10T can adapt to the requirements of different industries, and improve transportation efficiency. The dynamic load rating is 6.3T, and the static load rating is 13.6 T.

Stable Control System

The dock leveler can effectively adjust the height difference between the bottom of different transport vehicles and the vehicle platform through the control system. Ensure that the support of the platform table is more stable and strong so that the transportation process becomes smooth and the safety of the staff is guaranteed.

Safer Protective Facilities

The protection device adopts hydraulic control speed and an anti-fall valve to ensure that the support of the platform table is more stable and powerful.

Top 4 Detailed Demonstration of our Dock Leveller

Lip Details

Innovative double 5° arch bridge type reinforced tongue plate design technology.

Side Seal

Both sides are sealed with rubber strips to prevent dust from entering.

Motherboard stiffener

Ensure that the support of the platform table is more stable and powerful.

Dock Leveler Structure

- Tail lip

- Side curtain safety baffle

- Lip plate cylinder

- Platform support steel

- Lifting cylinder

- Hydraulic pump

- Sealing rubber strip

- Yellow and black warning strips

- Pedestal

- Control unit

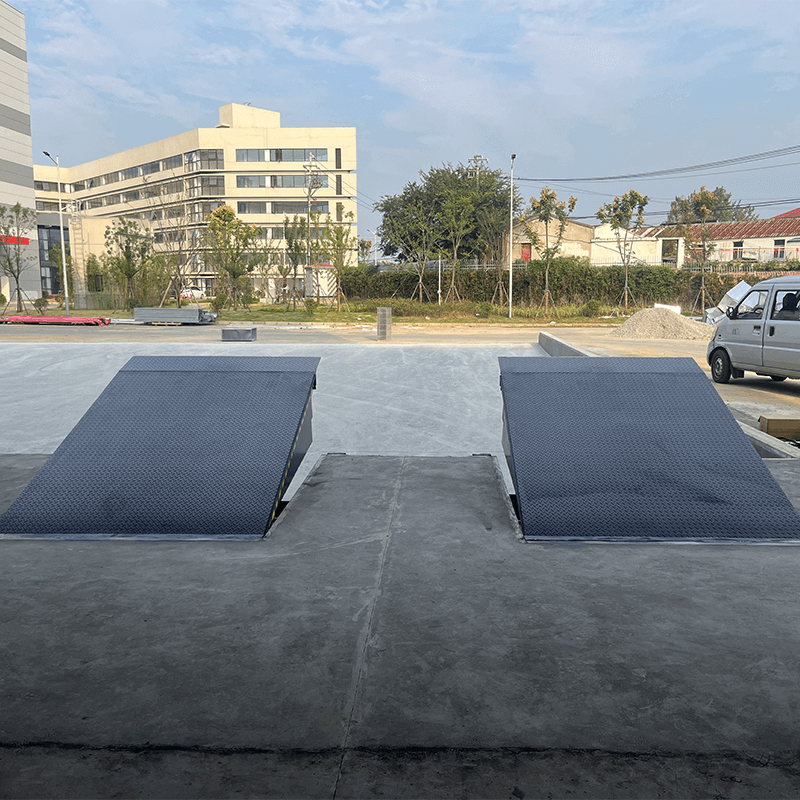

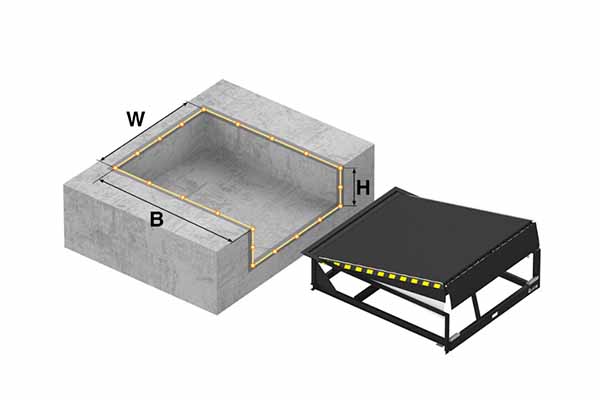

Installation conditions

About the dock leveler, we can design and offer you professional 3D and CAD drawings according to installation conditions. It’s very easy to install a dock leveler when the pit is ready well. It also makes your logistic work more convenient.

Common Types of Dock Levelers

Discover the most common types of dock levelers, and keep an eye out for unique designs exclusive to specific manufacturers.

Mechanical Dock Leveler

Mechanical dock levelers are designed for simplicity and durability, making them an excellent option for facilities with moderate traffic and basic operational needs. These levelers operate with a spring system and a manual pull chain, eliminating the need for electricity, which in turn helps reduce operational costs. With their straightforward design, mechanical dock levelers require minimal maintenance and provide reliable performance, making them a cost-effective solution for facilities with lower traffic volumes or budget constraints.

Edge of Dock Levelers

Edge of dock levelers are a simple and economical choice for smaller loading areas. These levelers are mounted directly on the dock face and offer a reasonable height adjustment range, making them well-suited for facilities with limited space and smaller budgets. They provide a safer and more ergonomic alternative to dock boards, reducing the risk of accidents. However, their use is generally limited to standard loading dock heights, typically for highway trailers. Despite this limitation, their affordability and safety features make them a popular choice for many businesses.

Vertical Dock Leveler

Vertical dock levelers offer a unique design that ensures a tight seal when positioned upright beneath the dock. Though they are hydraulically operated, they stay in a vertical position when not in use. This design feature allows the leveler to seal the door opening completely when raised, preventing conditioned air from escaping and maintaining an efficient warehouse environment. For logistics companies focused on cleanliness and energy efficiency, vertical dock levelers are an ideal solution, helping to reduce energy loss and maintain a controlled internal environment.

Loading Dock Scissor Leveler

Loading dock scissor levelers provide a reliable solution for varying truck heights, using a scissor mechanism for smooth, stable elevation adjustments. Hydraulically operated, they offer easy and safe operation, making them ideal for high-traffic environments. These levelers ensure efficient loading and unloading, even with frequent height changes.